Hydraulic Oil Filtration

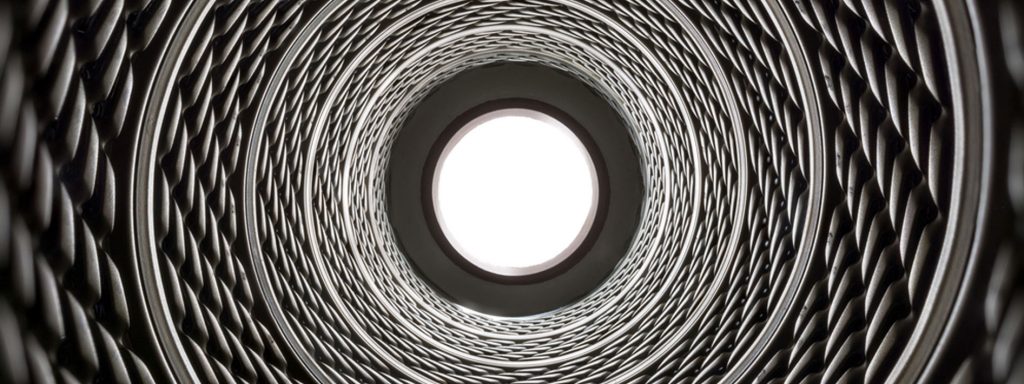

To meet OEM ISO cleanliness level specification hydraulic oil filtration is a key process designed to remove debris contaminants and wear metals in hydraulic oil systems, OMS LubriTek have made significant investments in custom designed and built filtration rig technology which incorporates a triple stage filtration process using absolute filters down to 1µm. The rig also incorporates in-line ISO cleanliness and water saturation monitoring systems. We can tell you instantly the cleanliness of the hydraulic oil and if any water contamination is present. Most importantly, we can tell you exactly how clean your hydraulic oil is at any stage of the filtration process.

If needed, hydraulic oil filtration would follow the oil analysis sampling and would involve one of our oil management technicians visiting site to carry out the filtration work on site. Production is not affected by filtration so there is no machine downtime. In fact oil circulation is recommended, as it will ensure the whole system has filtration carried out.

As with the initial oil fills, all filtration work is accompanied by certification of the ISO cleanliness level achieved to meet the OEM specification which gives our customers the knowledge that not only are they extending the life of internal components, but will also ensure warranties remain valid. For reference it has been proven that an improvement of just one ISO cleanliness code can result in a 10% to 30% increase in the life of contamination sensitive components such as nitrogen accumulators and servo driven pumps and valves.